SeaSpring ®, Dolphin Series |

Model No. |

Permeate Flow |

Design

Pressure |

Power

Required |

|

GPD |

LPD |

PSIG |

BAR |

HP |

KW |

A11 |

1400 |

5300 |

1000 |

69 |

6.6 |

5.0 |

A12 |

2550 |

9653 |

1000 |

69 |

6.6 |

5.0 |

A13 |

3475 |

13154 |

1000 |

69 |

6.6 |

5.0 |

A14 |

4200 |

15899 |

1000 |

69 |

6.6 |

5.0 |

A21 |

950 |

3596 |

1000 |

69 |

4.1 |

3.1 |

A22 |

1700 |

6435 |

1000 |

69 |

4.1 |

3.1 |

A23 |

2270 |

8593 |

1000 |

69 |

4.1 |

3.1 |

A24 |

2675 |

10126 |

1000 |

69 |

4.1 |

3.1 |

AH21 |

1200 |

4542 |

1200 |

83 |

8.0 |

5.9 |

AH22 |

2200 |

8328 |

1200 |

83 |

8.0 |

5.9 |

AH23 |

3000 |

11356 |

1200 |

83 |

8.0 |

5.9 |

AH24 |

3750 |

14195 |

1200 |

83 |

8.0 |

5.9 |

|

About

selection and application of your Dolphin

("A" Series) SeaSpring ® Desalination System

SeaSpring

® desalination systems utilize membranes

manufactured by Hydranautics, Inc., Manufacturer's performance predictions are based on

test criteria of; 800 PSIG feed pressure, a sodium chloride solution of 32,000 PPM, 77o

F (25oC) water temperature, and pH range of 6.5 to 7.0.

Performance projections for the Dolphin Series SeaSpring ® desalination systems are

based on 36,000 PPM seawater TDS at 77oF (25oC). |

Actual seawater composition and temperature

varies considerably from ocean to ocean and from open sea to bay waters. Seawater and bay

waters also undergo seasonal changes. Concentration of Total Dissolved Solids (TDS) in

seawater may vary from 30,000 to 45,000 PPM, and in rare situations can be as high as

60,000 PPM. All SeaSpring® desalination systems will operate under all seawater conditions (including

60,000 PPM TDS), and will produce water suitable for consumption. However, performance

ratings are based on operation under certain specified conditions. ASTM specification

#D1141 "Seawater Substitute" includes a universal "typical" analysis

for seawater. SeaSpring® desalination system performance ratings are based on operation on water with

this analysis, a TDS of 36,000 PPM, and temperature of 77oF (25oC).

Actual performance of the SeaSpring®desalination system (quality and quantity

of potable water produced) will vary from one site to another depending upon the factors

described above. To insure that the SeaSpring® desalination system you purchase performs

as you require, we have developed charts for all models indicating variations in

performance that are anticipated.

You can obtain information about seawater in your ocean and general area from the

NOAA web site http://www.ngdc.noaa.gov/cgi-bin/NOAAServer (NOAA seawater data site (Ocean temp, salinity, etc.

for all our oceans)).

|

Click Thumbnail |

| Chart

illustrating effect of seawater temperature on permeate quality and feed pressure. |

|

Click Thumbnail |

| Chart

illustrating effect of seawater salinity on permeate quality and feed pressure. |

|

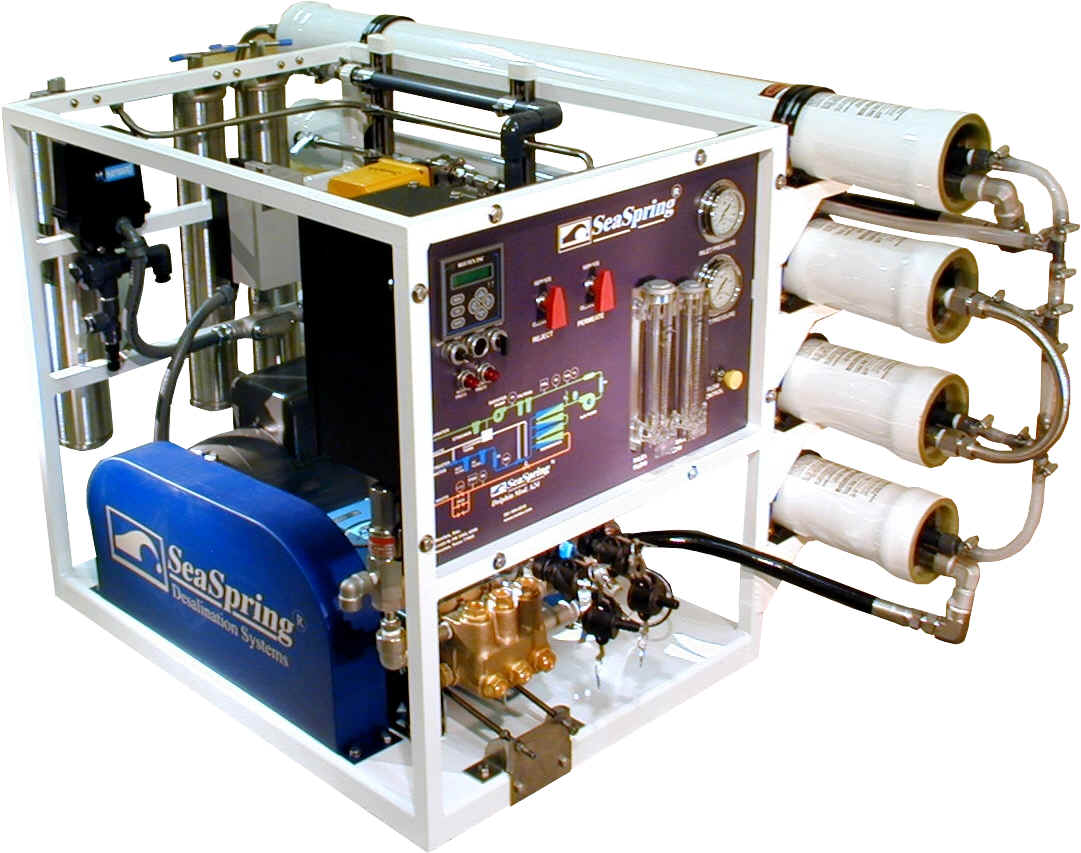

The

Dolphin Series (Series "A")

SeaSpring ® desalination systems are a group of mid range packaged systems ranging in

capacity from 900 GPD to 4,200 GPD.

Dolphin

units include basic components with features that stand out in the field of package

desalination systems common to all SeaSpring ® desalination systems.

Accept nothing less when you buy your water maker.

|

Cartridge Sediment Filters

|

Two cartridge sediment

filters in series are installed upstream of the membranes on every SeaSpring® desalination systems. Both filters are designed to use 1.0 to 25

micron elements. The primary filter will use either 10 or 20 micron elements, and the

secondary filter will use 5.0, 2.0, or 1.0 micron elements. |

|

The sediment

filter housings are designed to accept several different types of elements, and elements

are easily changed without special tools.

|

|

|

High pressure pumps for Dolphin Series desalination systems

desalination systems are belt driven CAT plunger pumps. Standard material of construction

is Naval Aluminum Bronze (NAB). |

|

Motor driver for the high pressure pump is

TEFC, 230/460 V AC, 3 ph, 60 Hz or 380 V AC, 3 ph, 50 Hz (specify voltage and frequency). |

|

|

| Pumps used on the

SeaSpring® desalination systems are sized to provide flow rate and pressure

required to perform as projected. Additionally, oversized motors are provided to

accommodate normal increase in pressure across the membranes. (As membranes age, the

amount of water produced through the membrane will decrease at a given pressure at the

membrane surface. This is a normal occurrence. However, if the pump is capable of

providing more pressure, the design product flow can still be obtained in most cases even

on membranes two or three years old.) Feed pump drivers are selected with

available horsepower to accommodate up to 30% increase in pressure (allowance for up to

10% per year decline in membrane performance). |

|

Membranes used in all SeaSpring ® desalination systems are spiral wound, polyamide, thin film composite type

manufactured by Hydranautics, Inc.. |

|

Dolphin Series, Model-A1 units have high capacity membranes that will remove 99.2% of

dissolved solids. This membrane is an economical membrane to operate and produces a high

volume of product. The "A1" units will provide drinking water at rated flow and

quality (less than 500 PPM total dissolved solids (TDS)) from seawater sources (up to

45,000 PPM salinity and seawater temperatures from 50oF (10oC) to 90oF (32oC).

(Based on ASTM D1141 standard seawater analysis.) |

|

Dolphin Series, Model-A2 and "AH2" use a High Rejection membrane. This

membrane will reject 99.5% of dissolved salts from the Seawater (providing better quality,

but less volume of product water). |

|

The Dolphin Series, Model-A2 will provide rated flow and quality when operating on

seawater with greater than 45,000 PPM salinity at seawater temperatures from 40oF (5oC) to

90oF (32oC). |

|

Dolphin Series, Model-AH2 units use the high rejection membrane, and are also designed

for operating at higher pressure. Higher operating pressure means you can produce even

better quality and a high volume of product as well, at all salinity and temperature

conditions mentioned above. The "AH2" series will typically produce the rated

amount of product water with salinity of less than 500 PPM TDS from seawater with salinity

up to 60,000 PPM. |

|

Membrane Pressure

Vessels

|

Pressure vessels used in model numbers

beginning "A1" and "A2" are highest quality fiberglass, designed for

operation up to 1,000 PSIG (69 BAR). |

|

Pressure vessels used on "AH2"

Models are of all stainless steel construction, designed for operation up to 1,200 PSIG

(83 BAR). |

|

Stainless steel pressure vessels are also

available for models "A1", and "A2" upon request |

|

|

| Monitoring

System

The Dolphin Series SeaSpring ® desalination system comes standard with all NEMA 4X corrosion resistant,

weatherproof controls in a console custom fitted into the unit frame. Basic operator

instructions are permanently printed on the control console. Wiring is labeled and

color-coded for easy troubleshooting.

|

|

On-Off-Automatic selector switch. Allows

operator to start, stop the unit, or operate from remote signal. |

|

Digital salinity monitor with dual cells

allows continuous monitoring of Inlet salinity and permeate salinity, as well as seawater

temperature. The monitor is also equipped with remote signaling outputs for recorder or

remote monitor, and alarm contacts. |

|

Liquid filled stainless steel pressure gauges

on all critical pressure lines. |

|

Flow indicators on inlet and permeate lines.

Indicators are mounted on control console. |

|

Low pressure shutdown switch on inlet to high

pressure feed pump. |

|

High pressure shutdown switch. Protects

membranes and housings from over pressuring. |

|

Automatic high-pressure dump valve, activated

automatically by high-pressure switch, can also be activated by operator for cleaning or

flushing membranes. |

|

Automatic permeate dump valve, activated

automatically by high permeate salinity (Dumps high salinity permeate overboard). Dump

valve can also be activated or overridden by operator from the control console. |

|

Click Thumbnail for process diagram |

Structural

Frame

|

Standard frames for your Dolphin Series SeaSpring ® desalination system are epoxy coated copper free aluminum. |

|

All fasteners and connectors are stainless

steel. |

|

Frame design is unique, allowing easy access

to membrane modules, high pressure pumps, and controls. Horizontal and vertical

configurations are available. |

|

Media filter, Neutralizing filter,

booster pumps are normally shipped separately, but can be packaged in a separate module

pre-fitted to the Dolphin frame upon request. |

|

Click thumbnail for dimensions |

Piping and Connections

|

Food grade tubing and fittings are used for

all materials contact with permeate. |

|

All high pressure connections are made with

stainless steel or high grade hoses that stand up to vibration and corrosion. |

|

System Maintenance Simplified

|

Your Dolphin Series SeaSpring® desalination system is equipped with an automatic flushing system to supply

fresh water to membranes every time the unit is shut down. |

|

Connections and valves are included to make

pickling or cleaning a simple task. |

|

Changing membranes is made simple by

break-a-way housing mounts and a fixture on the frame that supports the membrane housing

while servicing membranes. |

|

Individual sample valves for each membrane in

your system simplify troubleshooting fouling and scaling problems. |

|

| Easy

to Upgrade

All of the Dolphin Series SeaSpring ® desalination systems use the same frame, feed pump, cartridge filters, piping,

and instrumentation package. This commonality means that when your desalination

requirements increase, you can easily upgrade the Dolphin system to higher capacity (from 950 to 4,200 GPD) by simply changing membrane

type, adding membranes, or changing feed pump drive motor

|

| Optional Equipment for your SeaSpring® desalination system

Applications for

seawater desalination are not all the same, and your requirements are different from our

other customers. Your Dolphin Series SeaSpring® desalination system can be purchased with a wide variety of

options to make the best fit for your application and simplify installation.

|

Diesel or Gasoline Powered Units:

No external source of electrical

power required. (These commercial units are based on our Light Weight Water Purifier

design to meet US Government requirements for tactical drinking water supply.) They

can be transported easily in a half ton pick-up, and can be unloaded and placed in

operation by one person in less than one day.

|

Booster

Pump

|

Booster pumps are an optional item. The

system will not require a booster pump if sufficient pressure and flow is available from

your seawater supply source. |

|

Minimum pressure requirement for Dolphin Series is 15 PSIG

without media filters, 30 PSIG with media filters. |

|

Supply flow rate required depends upon the

size of the system (Systems with sand or multi-media filters will require additional water

for backwashing. PolyFilters do not require additional water.) |

|

Booster pumps are available with your SeaSpring TM desalination system in

all plastic, or stainless steel construction. When requesting a booster pump, specify

motor voltage, frequency. Standard motor enclosure is totally enclosed, fan cooled (TEFC)

close coupled to the booster pump. |

|

Media Filters

|

Media filters are required on seawater

applications when turbidity of seawater is expected to be high (greater than 20 NTU), or

when the SeaSpring® is to be installed on a mobile vessel operating in more than one location. |

|

Three types of media filters are available

for use on the Dolphin Series (Sand filter, Multimedia filter, or Up-Flow PolyFilter). All have

Fiberglass filter vessel designed for 100 PSIG operating pressure, with automatic valves

for operation and backwash. Sand and multi-media filters will remove suspended particles

larger than 25 micron in most applications. The PolyFilter will remove particles larger

than 10 micron. |

|

| Neutralizing

Filters (Mineralizers)

Product water from your SeaSpring

® desalination

system will normally have a lower pH than the seawater source. This is a characteristic of

the reverse osmosis seawater desalination process. The actual pH depends upon the salinity

and pH of the source seawater. Neutralizing filters available with the Dolphin Series contain a

media with calcium and magnesium carbonate (natural minerals found in all drinking water

supplies). When the product water passes through a neutralizing filter the pH is increased

to level that is less corrosive to your potable water distribution system, and some of the

natural minerals are restored, improving the taste of the water. Backwashing is not

required and media replacement should not be required more often than approximately once

per year.

|

Instrumentation Options

|

Hand held "Ultrameter", a useful

tool for operation and troubleshooting. Measures Conductivity, Resistivity, ORP, pH, and

Temperature of samples collected from system sample points. |

|

Differential pressure switch across cartridge

filters with alarm. |

|

Run time hour meter.

|

|

Potable

Water Disinfecting

|

Ultraviolet Sterilizer for point of use

disinfecting. |

|

Chemical feed system for injection of

chlorine or other residual disinfectant. |

|

Potable water storage tank with level

controls and distribution pump. |

|

Activated carbon filter to improve taste of

potable water and/or remove chlorine

|

|

| Stainless

Steel Feed Pump

Stainless steel construction is offered optionally for

the CAT plunger pump (Specify "S" after the model No.).

|

| Stainless Steel frame

Optional frame construction of polished stainless steel

is available. Specify "SS" after model number.

|

| Anti-scale

Chemical

Injection of an anti-scale chemical is a simple and

inexpensive way to preserve membrane life and reduce cleaning requirements.

The SeaSpring ® desalination system is available with a

compact, accurate chemical injection system complete with feed pump, and 7 gallon tank.

The feed system interfaces neatly with the Dolphin Series units.

The feed system may also be used for

injection of:

Chlorine

Bisulfite

Sodium Hydroxide

Mineral (for taste) |

|

| Other pages This Web

Site

SeaSpring®

is a trademark of Reetex, Inc.

|